What Kind of Sparks Will Be Created When Furniture Meets 3D Scanning?

01/06/25

Have you ever thought about how to better preserve those old furniture after years of baptism? Or have you ever thought about customizing a unique set of furniture according to your own preferences? Now, with the emergence of 3D scanning technology, these ideas have become within reach.

Digital Protection of Classical Furniture

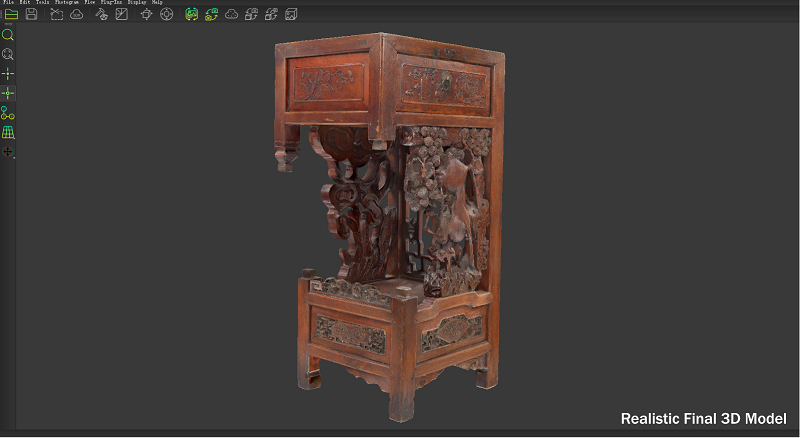

As a precious cultural heritage, the restoration and protection of classical furniture is particularly important. Traditional restoration methods often rely on the experience and skills of craftsmen, which are inefficient and difficult to guarantee the restoration effect. 3D scanning technology can accurately record the shape, size and texture of classical furniture, providing reliable data support for restoration work.

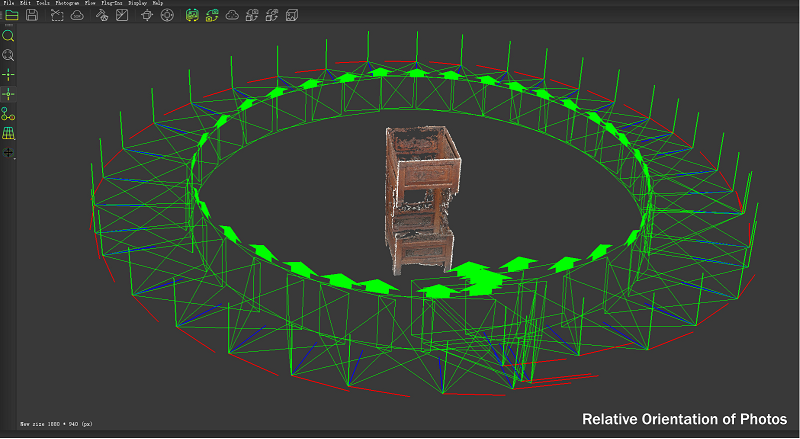

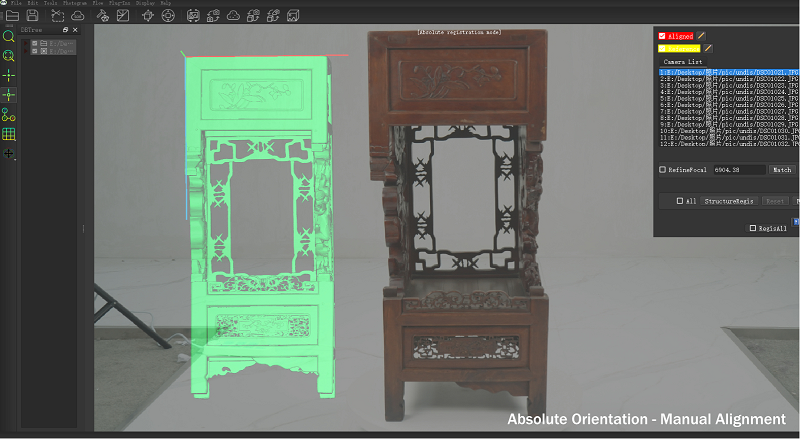

TrackScan-P42 3D scanning system of Scantech 3D is engineered with intelligent optical tracking measurement technology, allowing for direct scanning without the need for markers. This system is equipped with 7 parallel blue laser lines, boasting a high precision of 0.025mm. It can capture every intricate detail of a classic coffee table, thereby providing highly accurate 3D data.

In addition, the scanning function of a single blue laser can quickly obtain 3D information of deep holes and blind spots. Combined with the photos taken by the camera and processed by the 3DeVOK Mapping Software, a high-definition color 3D model can be quickly generated to realistically restore the texture details of classical furniture.

This technology not only makes the restoration of classical furniture more accurate and efficient, but also provides strong support for the protection of these precious cultural heritages. And these data can be used in virtual display, data archiving, learning and other fields.

Innovation In Furniture Design and Manufacturing

3D scanning technology can not only be used to restore classical furniture, but also bring new opportunities for the design and manufacture of modern furniture. Take mahogany furniture as an example. The production process of this type of furniture is complex and the production cycle is long. KSCAN laser 3D scanner of Scantech 3D can effectively meet these challenges.

KSCAN handheld 3D scanner is equipped with 11 parallel infrared laser lines, which can cover a scanning range of 1440 mm x 860 mm, and can realize the rapid acquisition of large-area objects. It provides accurate 3D data support for design, improvement and production, helps to improve work efficiency, and optimizes CAD drawing production, product improvement and processing and production processes.

Using 3D scanning technology, designers can quickly verify the feasibility of design solutions, and make modifications and optimizations, thereby shortening product development cycles and reducing production costs. In addition, 3D scanning also supports customized furniture design and production based on user personalized needs, better meeting the personalized needs of the market.

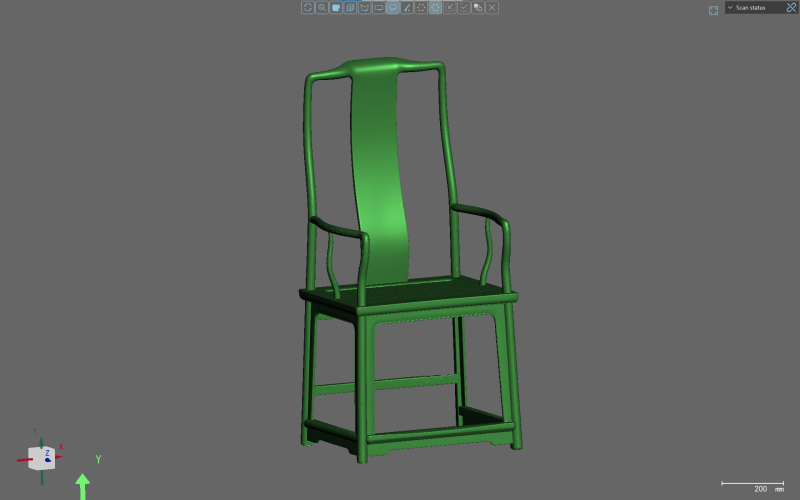

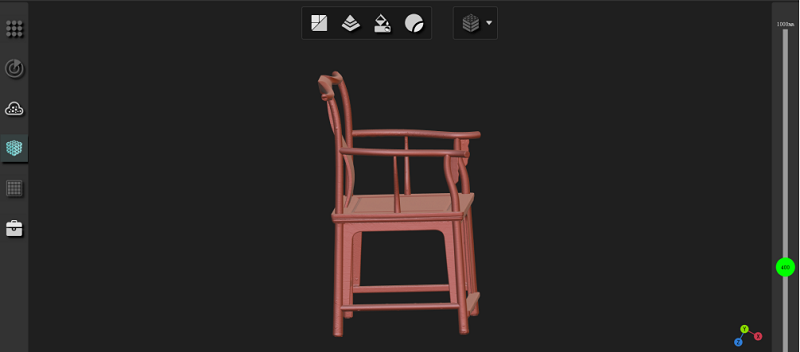

Red Reflective Paint? No Need for Spray Powder, Easy to Scan

In the face of challenges that furniture designers often encounter, such as dealing with reflective and smooth surfaces, traditional 3D scanning technology often requires spray powder, which is not only time-consuming and labor-intensive, but may also affect scanning accuracy. The narrow or thin edge parts of wooden chairs are relatively difficult to scan, and the iReal M3 dual–infrared laser 3D scanner can solve these problems well.

The device uses two light source modes, including 2 infrared VCSELs and 7 infrared parallel laser lines, which effectively improves the scanning performance. We chose the 7 infrared parallel laser lines mode for this scan.

Compared with infrared speckle mode, infrared parallel laser line has the following two advantages when scanning objects:

- It can scan black, dark and reflective objects without scanning spray;

- It has higher edge reconstruction accuracy, better detail restoration and clearer edges and corners.

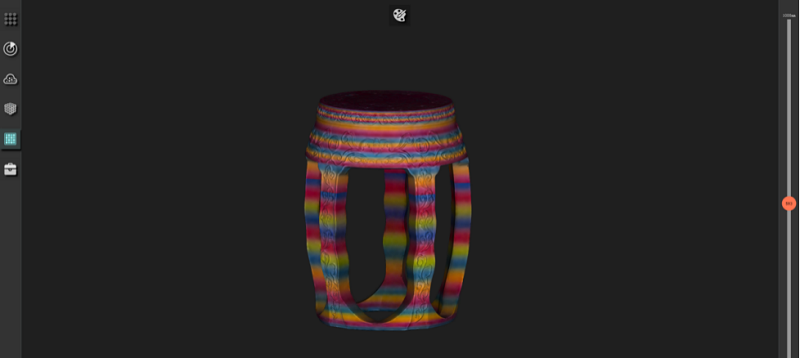

3D Color Scanning and Printing, Turning Ideas Into Reality

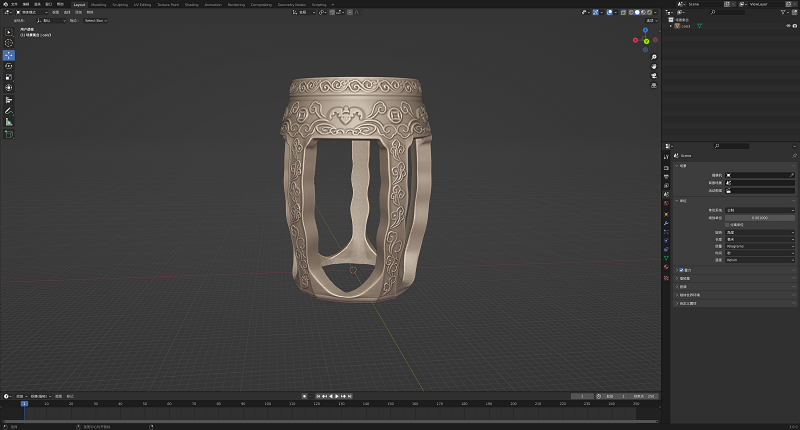

This retro-style colorful stool is made by FDM (fused deposition modeling) mixed color 3D printing technology. The 3D printing process takes about 120 hours, and the final product accurately shows every detail of the stool, including color, texture and pattern.

The iReal 2E color 3D scanner is equipped with 3 infrared VCSELs. It does not require markers or contact with the scanned object, and supports capturing 24-bit RGB true color data, which can quickly obtain a complete color 3D model. Its speckle surface scanning method is particularly suitable for scanning medium and large objects (>30cm). The device boasts a wide field of view (FoV) measuring 580x550mm and a substantial depth of field reaching 720mm, which guarantees ease and flexibility in operation. With iReal 2E, you can easily capture the 3D data of the 3D printed color stool, providing strong technical support for the realization of creativity.

Whether it is the restoration of classical furniture or the design and manufacture of modern furniture, 3D scanning technology plays an important role. It can not only help us better protect and inherit classical furniture, but also bring new possibilities for the design and manufacture of modern furniture. With the continuous development and application of technology, 3D scanning technology will play an increasingly important role in the furniture industry and bring more beauty to our lives.

Related Articles

View Our Product