How a 3D Scanner Help With Reverse Engineering?

03/04/25

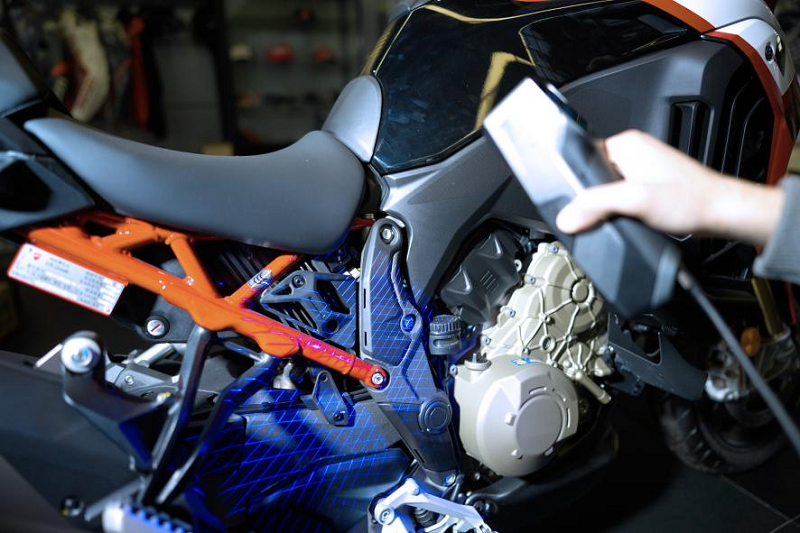

In the rapidly evolving field of industrial design, reverse engineering serves as a pivotal technical method, playing a crucial role. It is a process that replicates the design technology of a product, involving the reverse study and analysis of existing products to derive their relevant parameters and characteristics. This enables the creation of product models that are structurally similar but with enhanced performance. As an essential tool in reverse engineering, 3D scanners are gaining industry focus due to their high precision and efficiency.

Reverse Engineering And 3D Scanning Technology

In essence, reverse engineering is the process of measuring and analyzing a physical product without the original design drawings or documentation. This process involves data processing and the reconstruction of geometric models, which are then used to generate CNC (Computer Numerical Control) programs for the re-manufacturing of the product.

Before the widespread application of 3D scanning technology, reverse engineering primarily relied on manual measurements. This method, especially for parts with complex surfaces or structures, was not only time-consuming and labor-intensive but also difficult to ensure precision. The advent of 3D scanners has dramatically changed this situation, making the reverse engineering of physical products much faster and more accurate.

The Application of 3D Scanners in Reverse Engineering

High-Precision Data Collection: 3D scanners are capable of quickly capturing the geometric shapes and texture information of an object’s surface, generating high-precision 3D point cloud data. These 3D data serve as the foundation for reverse engineering, ensuring the accuracy of the reconstructed models.

Complex Geometric Shape Handling: Traditional measurement methods often struggle with products that have complex geometric shapes. 3D scanners, through non-contact measurement, can easily handle complex surfaces and internal structures that are difficult to access.

Rapid Prototyping: The 3D data obtained from 3D scanners can be quickly converted into 3D scanned models, which can then be used for 3D printing or CNC (Computer Numerical Control), significantly reducing the product development cycle.

Quality Inspection and Comparison: In addition to reverse engineering, 3D scanners are also used for quality inspection. By comparing the 3D scanned data with the original design model, deviations and defects in the manufacturing process can be quickly identified.

The Advantages of 3DeVOK MT 3D Scanner

Taking the 3DeVOK MT professional 3D scanner as an example, its technological innovation further exemplifies these application values. The 3DeVOK MT handheld 3D scanner inherits SCANTECH (HANGZHOU) CO.,LTD’s industrial-grade professional expertise and incorporates an innovative three-light-source technology to meet a variety of application needs.

Below are the key advantages of the 3DeVOK MT portable 3D scanner:

Multi-Light Source Precision Scanning: Combining 34 blue laser lines, 22 infrared laser lines, and a large-area infrared speckle, it can adapt to products of different materials, environments, and complexities, ensuring the accuracy of the 3D scan.

High Resolution and Detail Capture: Utilizing 17 pairs of crossed blue laser lines, along with marker alignment stitching technology, it achieves a basic accuracy of up to 0.04mm, a volume accuracy of 0.04+0.06mm/m, and a point spacing as low as 0.05mm (the recommended scanning setting is between 0.1-3mm). This excels in capturing fine surface details.

Efficient Scanning Speed: The 3DeVOK MT infrared 3d scanner boasts high-speed scanning capabilities, with a scanning frame rate of up to 70 frames per second and a scanning speed of 4,500,000 points per second, allowing for the rapid completion of scanning large surface areas and quickly obtaining the complete 3D data of objects, thus improving work efficiency.

Portability and Ease of Use: The device is designed to be lightweight, weighing only 0.62kg, making it easy to carry and operate, suitable for on-site use, and meeting scanning needs in various scenarios.

Software Compatibility: It supports common 3D data formats such as *.asc, *.stl, and *.obj, and can seamlessly integrate with a variety of reverse engineering 3d software, simplifying the design process.

The application of 3D scanners in reverse engineering not only enhances the precision and efficiency of data collection, but also significantly reduces the product development cycle. The 3DeVOK MT 3D scanner, with its advantages such as multi-light source precision scanning, software compatibility, and high-efficiency scanning speed, has become a powerful assistant in reverse engineering. By further optimizing data processing capabilities, improving scanning accuracy, and expanding application scenarios, 3D scanners will play an even more crucial role in future industrial design.

Related Articles

View Our Product