How to Choose a Professional 3D Scanner?

02/28/25

In the digital era, 3D scanners have become an essential tool across numerous industries, ranging from industrial manufacturing to cultural creativity, as well as from cultural relic preservation to medical rehabilitation, with their application scenarios expanding increasingly. However, faced with a multitude of brands and models, how does one choose the most suitable 3D scanner for their needs?

I. Define Your Needs: Application Scenarios Are Key

Before selecting a 3D scanner, it is crucial to clarify your intended application scenario, as different industries have varying requirements for scanners. For instance:

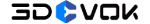

– Industrial Manufacturing: High precision and efficiency are required for product design, quality inspection, and reverse engineering. The scanner should have high accuracy, high resolution, and the ability to adapt to complex geometries.

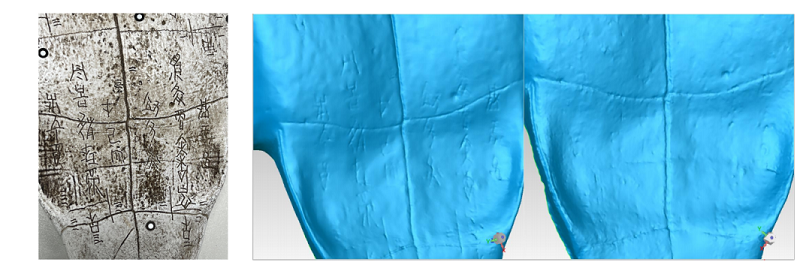

– Cultural Relic Preservation: There is a high demand for color fidelity and detail capture to accurately reproduce the appearance and texture of artifacts without causing damage.

– Medical Rehabilitation: 3D scanners must be capable of scanning human body and have eye-safety certifications, while also being able to quickly and accurately capture body surface 3D data.

– Cultural and Creative Industries and Artistic Design: These fields prioritize the flexibility and ease of use of the scanner to swiftly capture creative inspiration and convert it into digital models.

II. Technical Parameters: Precision, Speed, and Compatibility

– Precision: Precision is one of the core indicators of a 3D scanner, directly determining the quality of the 3D scan data. Precision is usually categorized into point accuracy and alignment accuracy. Point accuracy refers to the accuracy of individual scan points, while alignment accuracy pertains to the overall accuracy after multiple scan datasets are combined.

– Scan Speed: The speed of the scan determines the efficiency of the work. For scenarios that require rapid data acquisition, such as 3d body scanning or large-scale production, scan speed is of paramount importance.

– Compatibility: The compatibility of a 3D scanner includes software and hardware compatibility. The scanner should support mainstream 3D modeling and CAD software and be compatible with computer systems and other devices.

III. Scanning Technology: Light Source

The type of light source in a 3D scanner significantly impacts its scanning capabilities and range of applications. Commonly available light source types in the market include infrared VCSEL (speckle scanning), line laser (cross-line/parallel light scanning), and LED (speckle/grating scanning). For example, the 3DeVOK 3D scanner employs advanced light source technology to adapt to various scanning needs.

Light sources used in the 3DeVOK scanner:

– Infrared VCSEL Speckle Light Source: Suitable for scanning materials that are black or highly reflective, particularly adept at scanning medium to large objects (≥30cm).

– Infrared Parallel Laser Light Source: Enhances scanning speed and accuracy, with enhanced scanning capabilities for objects with rich colors such as red, yellow, and green.

– Crossed Blue Laser Light Source: Offers higher detail restoration, ideal for high-precision and detail-demanding object scanning, such as cultural relics and artworks.

(1) Infrared Parallel Laser vs. Infrared VCSEL Speckle

The iReal M3 3d laser scanner employs a dual-infrared source technology with 7 infrared parallel laser lines plus infrared speckle, whereas the iReal 2E handheld 3d scanner uses only the infrared speckle. Consequently, the M3 surpasses the 2E in terms of material adaptability, scanning range, and data acquisition capabilities.

Material Adaptability – bright white reflection: infrared parallel laser, good reflective adaptability, better data surface quality, high data integrity

Material Adaptability – black and bright tires: infrared parallel line laser, good adaptability to black, good details, high data restoration

Infrared parallel line laser, good hole edge data accuracy and high data restoration

Detail Restoration: Infrared parallel line laser, more detailed restoration

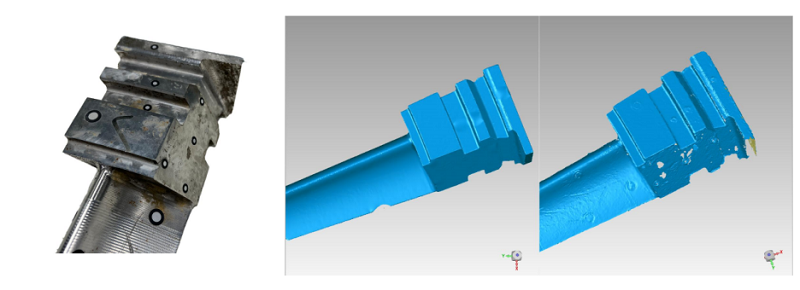

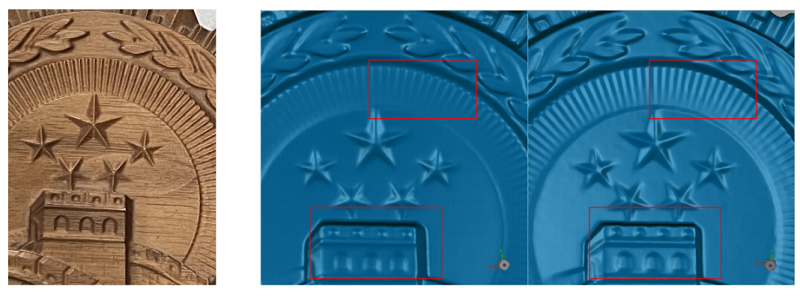

(2) Infrared Laser vs. Crossed Blue Laser

The newly launched 3DeVOK MT professional 3D scanner features an innovative 3-light source technology (34 blue laser lines + 22 infrared laser lines + Large-area infrared speckle), which surpasses both the M3 and 2E in terms of material adaptability, scanning environment, scanning speed, scanning range, and data acquisition capabilities.

Compared to infrared laser, crossed blue laser offers stronger detail restoration capabilities.

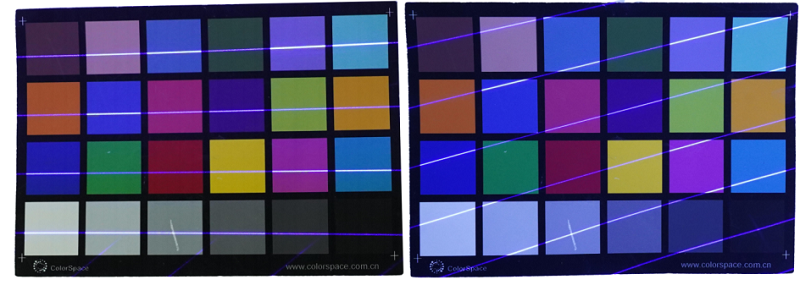

(3) Infrared Laser vs. Other Blue Lasers (Laser Class 1)

Blue light is absorbed by yellow, so blue light is less capable of scanning yellow objects. Infrared lasers are less absorbed by yellow, so when faced with (bright) yellow objects, infrared scanning capabilities are stronger.

IV. Usability and Portability

– Usability: The user interface and functional design of a 3D scanner directly affect the user experience. For instance, the 3DeVOK Studio scanning software comes with real-time partial precision scanning, intelligent color mapping, and automatic save features, allowing even novice users to quickly get the hang of it.

– Portability: For users who need to operate in various settings, the portability of the scanner is crucial. The 3DeVOK MT portable 3D scanner weighs only 0.62 kg, is compact in size, and easy to carry, making it suitable for outdoor or on-site environments.

V. Budget

Budget is an important consideration when choosing a 3D scanner. The price range of different scanners can vary widely, from a few thousand to several hundred thousand Chinese yuan. The budget directly determines the range and performance of scanners available for selection.

VI. Brand and After-Sales Service

Choosing a well-known brand and reliable after-sales service is crucial for ensuring a positive user experience. As a professional brand under SCANTECH, 3DeVOK offers comprehensive after-sales services, including online demonstrations, remote guidance, and warranty services.

VII. Product Recommendations

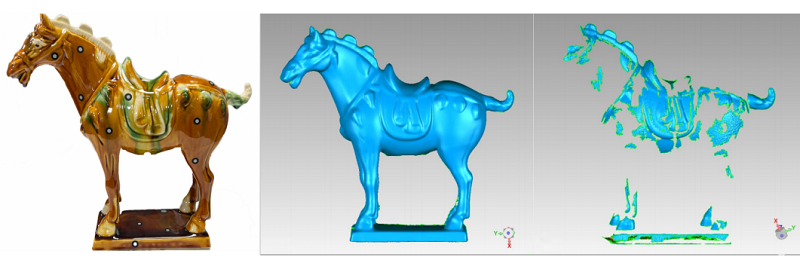

The 3DeVOK team under SCANTECH has launched three highly cost-effective handheld 3D scanners: the 3DeVOK MT professional 3D scanner, the iReal M3 laser 3D scanner, and the iReal 2E handheld color 3D scanner. Here is a detailed comparison of the three scanners:

|

3DeVOK MT VS. iReal M3 VS. iReal 2E |

||||

|

Comparison Items |

3DeVOK MT |

iReal M3 |

iReal 2E |

|

| Product Differences | Number of Light Sources | 3 Light Sources | 2 Light Sources | 1 Light Source |

| Light Source 1 | 1 Infrared VCSEL (Invisible Light) |

2 Infrared VCSELs | 3 Infrared VCSELs | |

| Light Source 2 | 22 Infrared Laser Lines(Invisible Light) | 7 Infrared Parallel Laser Lines | / | |

| Light Source 3 | 34 Blue Laser Lines | / | / | |

| Scanning Mode | Crossed Laser Lines+Infrared Parallel Laser Lines+Speckle-Surface Scanning | Infrared Parallel Laser Lines+Speckle-Surface Scanning | Speckle-Surface Scanning | |

|

Scanning Performance |

Accuracy | Up to 0.04 mm + 0.06 mm/m (Marker Alignment) |

Up to 0.25mm/m | Up to 0.3mm/m |

| Point Distance | Blue laser mode 0.05-5mm;

Infrared laser mode 0.1-5mm; Speckle mode regular scanning 0.2-5mm; Local fine scanning 0.1-5mm |

Parallel line mode: minimum dot spacing 0.1mm; Speckle mode: minimum dot spacing 0.2mm. | Minimum point spacing 0.2mm (only in speckle mode) | |

| Recommended Object Size | Laser mode recommended scan size ≥ 0.05m; Speckle mode recommended scan size ≥ 0.3m |

Recommended scan size ≥ 0.3m (speckle mode only) | ||

| Recommended Scanned Objects | Precision requirement: ±0.04+0.06mm/m, virtually no scanning limitations. Suitable for artifacts, human body, industrial design, aerospace scanning. | Low precision requirement (0.25mm/m), nearly unlimited scanning. Suitable for human body, industrial designs, and art carvings. | Human bodies, medium to large sculptures, and items with relatively low detail requirements (such as car mats) | |

| Material Adaptability | Most dark, shiny, and reflective objects can be scanned without scanning spray. | Scanning spray is needed to scan most dark, shiny, and reflective objects. | ||

| Color Adaptability | For objects with richer colors such as red, yellow, and green, the infrared parallel line laser has a stronger scanning ability. | The pattern brightness of 3 VCSELs will be slightly stronger, and the black scanning ability will be slightly stronger. | ||

| Scanning Speed | Blue and infrared laser up to 70 FPS (Marker Alignment), up to 30 FPS (Hybrid Alignment),

speckle mode up to 30 FPS |

Parallel line laser mode up to 60 FPS; Speckle mode up to 15 FPS | Up to 15 FPS (speckle mode only) | |

| Outdoor Scanning | Support | |||

Selecting the right 3D scanner requires a comprehensive consideration of factors such as the application scenario, technical specifications, scanning technology, ease of use, brand, and after-sales service. The 3DeVOK range of scanners, including the MT, M3, and 2E, each have their unique features and are capable of meeting the diverse needs of different users. Whether you are an industrial designer, a cultural relic preservation specialist, or a cultural and creative professional, you can find the most suitable 3D scanning solution within the 3DeVOK product line.

It is hoped that this article provides valuable reference for your selection of a 3D scanner. If you still have questions about 3D scanners, feel free to consult the professional team at 3DeVOK at any time. We will offer you all-around support and service.

Related Articles

View Our Product