Tech For Good | Application of 3D Scanning Technology in Medical Equipment

12/31/24

As technological advancements surge forward, the application of 3D scanning technology in the medical field is gradually deepening, providing a new perspective for precision medicine and personalized treatment. This technology supplies designers and medical professionals with comprehensive data by precisely capturing the 3D data of medical devices. Based on this data, reverse engineering design is carried out, and customized production of medical devices achieves higher precision. The high-precision 3D scanning technology of SCANTECH (HANGZHOU) CO.,LTD plays a pivotal role in driving this process forward.

Accurately Representing the 3D Shape of Medical Devices

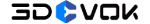

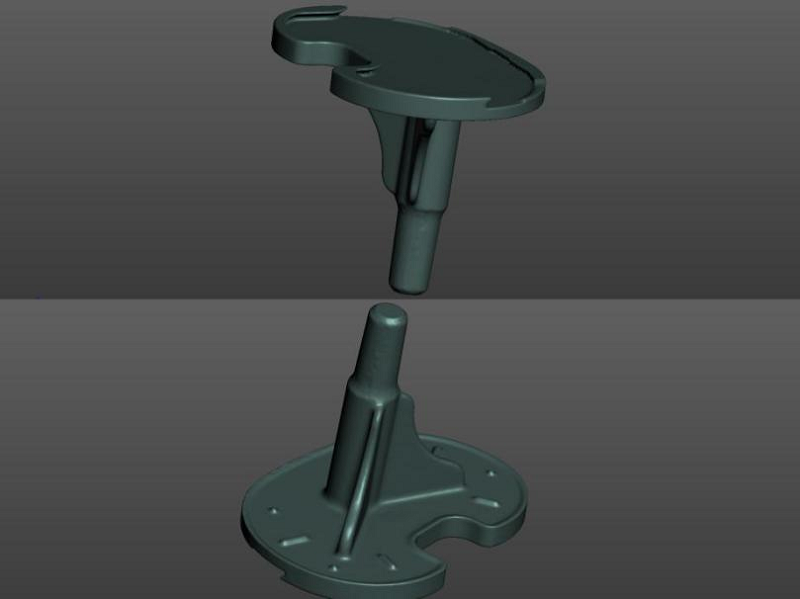

The SIMSCAN handheld 3D scanner, equipped with 17 parallel blue laser lines, boasts exceptional detail capture capabilities. It can efficiently and accurately capture the tiny features and complex curved surface information of precision workpiece surfaces. For small (<5cm) and detailed reflective medical devices, such as surgical instruments, the scanner can obtain more complete and detailed 3D models through powder spraying, providing an important reference for the design and manufacture of medical devices.

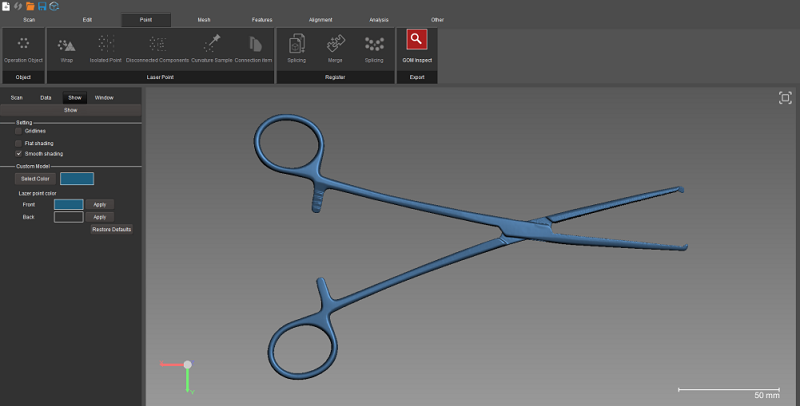

Reverse Engineering Accelerates Innovative Design of Medical Devices

The SIMSCAN laser 3D scanner employs 63 blue laser lines to quickly evaluate the geometric information and dimensions of the workpiece. With its high accuracy (0.02mm) and wide maximum scanning area (700 mm x 600 mm), it is instrumental in the reverse engineering of medical devices. This large-scale scanning capability enables the scanner to rapidly capture the fine details of metal medical tools, such as precision surgical scissors, and directly generate 3D scan models without the use of scanning spray. This efficient scanning process can not only greatly improve the efficiency of device prototyping, but also provide the ability to respond quickly to the innovation and optimization of medical devices.

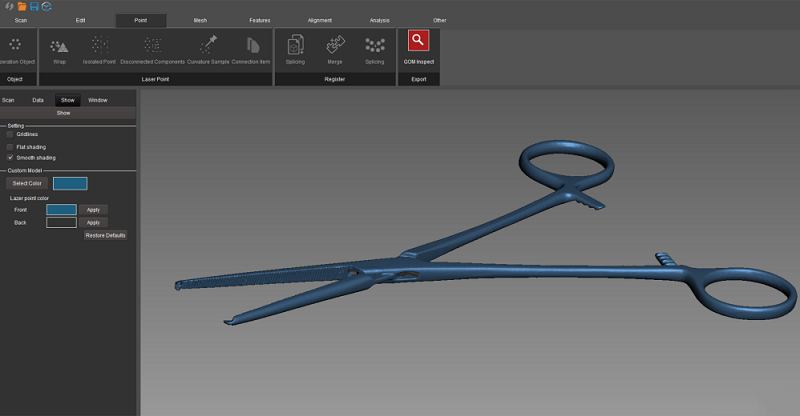

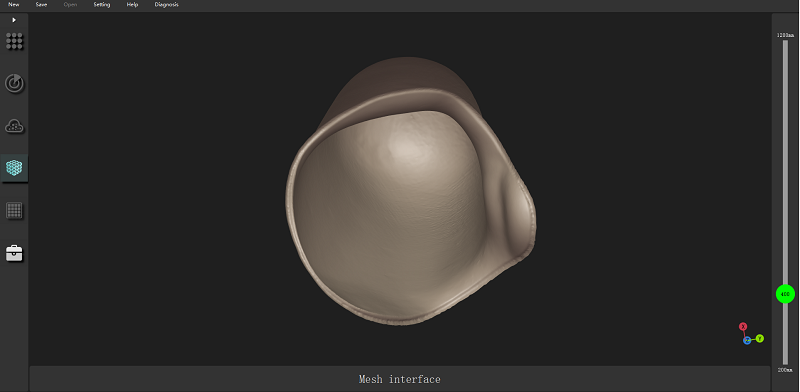

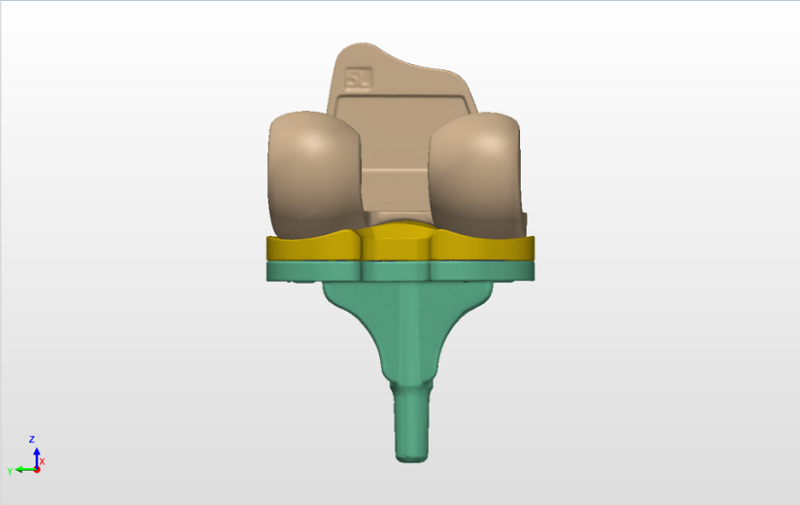

Virtual Assembly Improves the Accuracy of Treatment Plans

SIMSCAN portable 3D scanner can obtain high-precision 3D models without spray powder when processing highly reflective artificial knee joint components. Combined with Polyworks software (a professional 3D measurement tool mainly used for dimensional analysis and quality control, supporting the general workflow of multiple 3D measurement devices), doctors can perform precise alignment operations, improve the accuracy of medical simulation research, and customize more accurate treatment plans for patients.

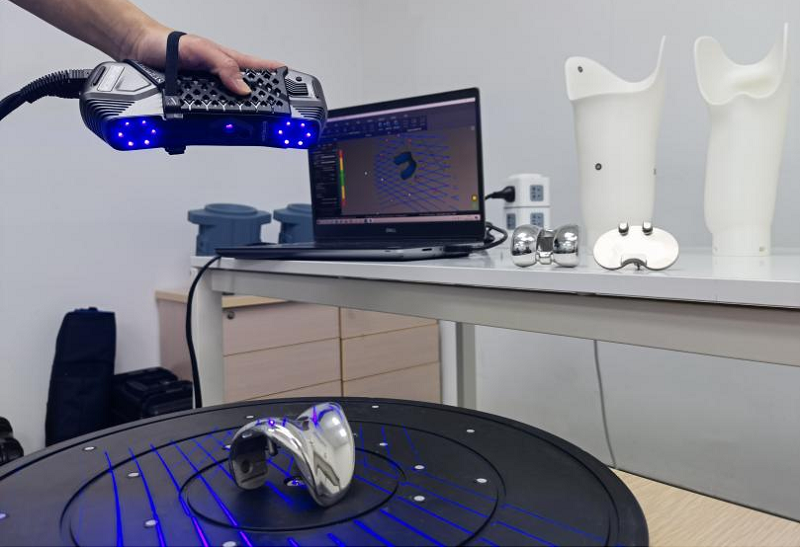

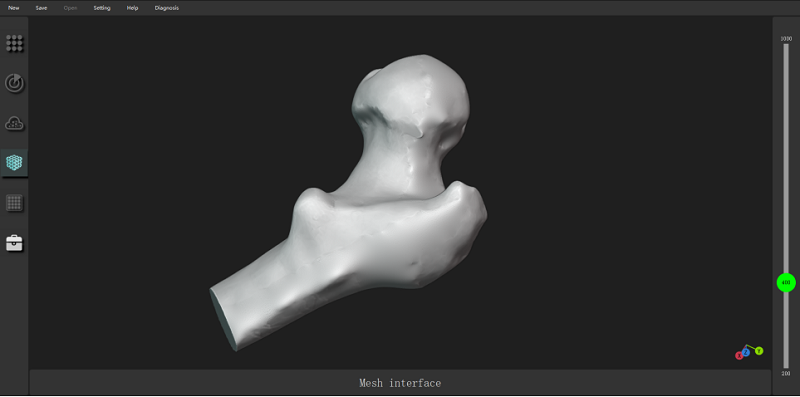

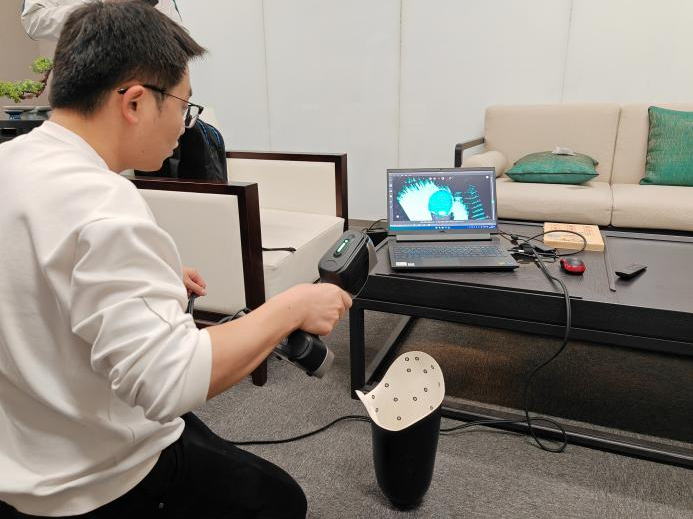

Versatile 3D Scanners Aid Surgical Planning and Implant Design

The iReal M3 dual-infrared laser 3D scanner, presented by Grupo Abstract at the 3rd International Congress of 3D Printing & Health, features two light source modes (2 infrared VCSELs and 7 infrared parallel laser lines), suitable for human body digitization and medical specimen scanning, such as bone models. This technology provides new perspectives for surgical planning and customized implant design.

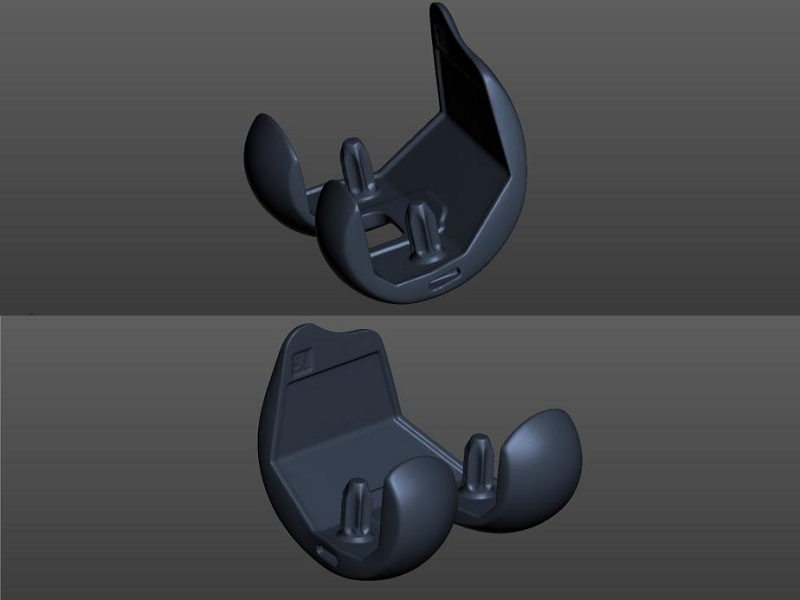

Customized Prosthetic Socket

The infrared parallel laser line equipped in iReal M3 color 3d scanner supports scanning objects as small as 5 cm, which can ensure the accuracy of the scanning process. Its maximum accuracy can reach 0.1mm. The acquired prosthetic socket edge data is clearer and more suitable for customized design, providing solid technical support for creating personalized prosthetic sockets that are both comfortable and tightly fitting.

The 3D scanning technology of SCANTECH (HANGZHOU) CO.,LTD not only accelerates the design and production of medical devices, but also brings patients accurate and personalized treatment plans. Looking to the future, with the continuous advancement of 3D scanning technology, we have reason to believe that the design and application of medical devices will be more humane and intelligent, and better serve human health.

Related Articles

View Our Product