Why Is 3D Scanning Needed In the Automotive Industry?

03/07/25

In today’s era of rapid technological advancement, the automotive industry is undergoing unprecedented transformation. From traditional manufacturing to intelligent production, and from fuel vehicles to new energy vehicles, each technological innovation drives the progress of the industry. Among these advancements, 3D scanning technology, with its unique advantages, is gradually becoming an indispensable helper in the automotive sector.

In-Depth Applications of 3D Scanning Technology in the Automotive Field

3D scanning technology is extensively applied in the automotive field, encompassing a wide range of applications including design optimization, reverse engineering, prototype creation, model building, as well as fault analysis, assembly guidance, dimension measurement, virtual simulation, digital archiving, and production process optimization. It plays an irreplaceable role. Take the 3DeVOK MT professional 3D scanner as an example; its multi-light source technology (34 blue laser lines, 22 infrared laser lines and Large-area infrared speckle) enables the digital conversion of automotive parts to be fast and accurate.

Case Study One: Design and Optimization of the Car Hood

In the inspection of car hoods, the 3DeVOK MT professional 3D scanner, equipped with 34 blue laser lines and combined with marker alignment technology, boasts a basic accuracy of up to 0.04mm, as well as a scanning frame rate of up to 70 frames per second and a scanning speed of 3,300,000 points per second. This enables the rapid acquisition of high-precision 3D data, assisting engineers in identifying and correcting potential design and manufacturing defects at an early stage. Moreover, the handheld 3D scanner has strong adaptability to materials, efficiently scanning even reflective surfaces without the need for spray powder in most cases. This advanced scanning technology, which easily overcomes reflective surfaces, not only guarantees that the product’s appearance and dimensions align with design requirements but also drastically shortens the development process.

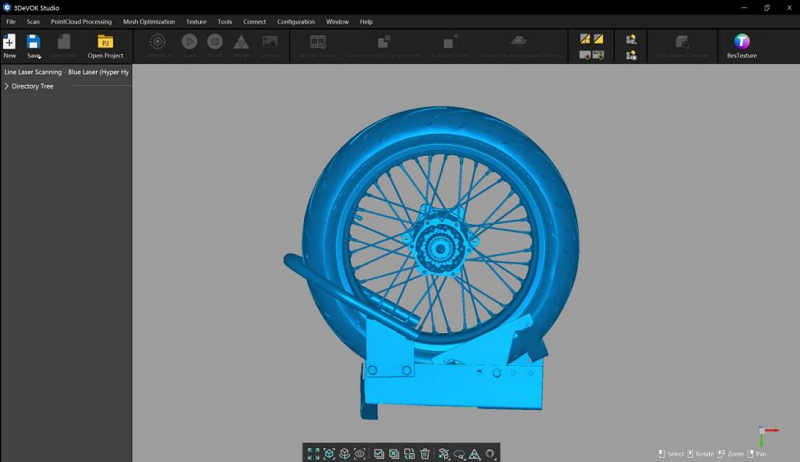

Case Study Two: Ergonomic Design of Car Seats

The 3DeVOK MT portable 3d scanner excels in the design and quality control of car seats. Its 22 infrared laser lines technology demonstrates exceptional adaptability to multicolored materials, particularly yellow and red, ensuring the precision of 3D scanning and the true color restoration. Thanks to the high scan rate of the blue laser (up to 70 frames per second) and the rapid scanning speed (3,300,000 points per second), the 3DeVOK MT can quickly capture the complete 3D data of the seat, providing strong technical support for enhancing seat comfort, conducting quality inspections, and even customizing seat covers. With this efficient digital design approach, automotive manufacturers are better able to meet consumers’ stringent demands for seat comfort and safety.

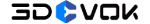

Case Study Three: Precise Measurement and Quality Control of Automotive Tires

As a critical component that comes into contact with the ground, the quality of automotive tires is directly related to driving safety. The blue laser mode of the 3DeVOK MT infrared 3d scanner offers excellent material adaptability, often requiring no spray powder even when scanning reflective or dark objects. Specifically for black automotive tires, the 3DeVOK MT can quickly and accurately capture the 3D data of the tires, enabling precise measurement of the tire profile, tread depth, and uniformity. This high-precision measurement not only ensures the quality of the tires but also enhances production efficiency.

In addition, the 3DeVOK MT 3d color scanner offers a range of advantages such as no markers needed, lightless scanning, and support for various materials and environments. These features enable it to easily handle the diverse and complex scenarios within the automotive industry, such as scanning in direct outdoor sunlight or in dark environments. Its powerful data collection capabilities and high-precision scanning results provide solid technical support for the digital transformation of the automotive industry.

The application prospects of 3D scanning technology in the automotive industry are broad. With its outstanding performance and versatility, the 3DeVOK MT 3D scanner is becoming an important tool for automotive manufacturers to achieve efficient production, optimize design, and enhance quality. Whether it’s model construction in the design phase or quality control during the production process, the 3DeVOK MT offers stable and efficient support.

Related Articles

View Our Product