Matters Needs Attention During Scanning

Scanning Objects

Most Suitable Material

The matte and light-colored items are easily spliced when scanning.

Colorful objects: The mapping result will be better.

It has obvious color differences when scanning a single-colored object using the Colorful Object Scanning Mode.

Spray is required for the objects that are black, transparent, and highly reflective.

Optimal Size

More than 25cm

Spray

The scanningspray is often spraved on the surface of the object before scanning so that the surface presents a good diffuse reflection shape. It effectively improves the scanning data quality, makes the surface black, reflective, transparent, and other objects easier to scan, and obtains high-quality point cloud data.

Material |

Examples |

Reasons |

|---|---|---|

Transparent material |

Glasses Transparent Plastic Jelly |

As the scanner light will penetrate the glass, the camera cannot accurately capture the position of the reflected light, so the scanner cannot scan it; If it is a translucent object, the reflected light signal received by the camera is insufficient to complete data acquisition. In addition, impurities in translucent articles will affect the reflected light, and the disordered reflected light will lead to incorrect data acquisition. |

Penetrating Material |

Jade Jadeite |

When the scanner light hits the object’s surface, it will penetrate into the interior of the object, causing the light position captured by the camera not the object’s surface contour, thus affecting the accuracy of the scanning data. |

Highly Reflective Material |

Mirror Highly Reflective Metal Surface |

The camera should have captured the diffuse reflection light after the scanner light hits the object surface, while highly reflective materials such as mirrors will have mirror reflection on the light because the surface is too smooth, making the two cameras of the scanner unable to capture the reflected light at the same time, so they cannot scan. |

Dark Black Object |

Black Vase Black Leather |

Because black objects absorb light, there is less light information reflected to the camera, so the scanning speed will slow down or the data will not come out. |

Scanning Speed

Although the iReal scanner is very fast, remember not to scan it too fast, because you can’t know if you have scanned some dead corners. Instead, you need to rescan the object from all angles. Rescanning is also the process of checking the scanning data. You can also use: Data Quality Color Map to view the scanning data. It is better to scan the model green.

If the above requirements are not followed, the data may be noisy or orange peel.

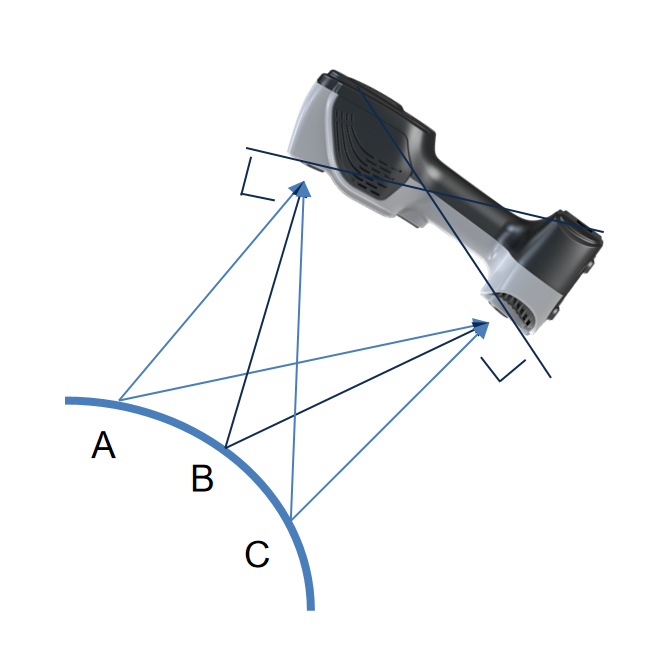

Scanning Angles

If the two black and white cameras both keep a nearly vertical angle (point B in the figure), the scanning angle can be the best with the largest amount of points, and A and C with the least amount of points.

Scanning Distance

It’s optimal to keep the distance between the scanner and the object from 250mm to 450mm during scanning which can help capture high-quality 3D data.

The scanner is based on camera imaging, so there is a problem with depth of field. The scanning distance of the scanner is 280mm - 1000mm, 720mm in total.

Sometimes we need to limit the farthest or closest scanning distance to filter objects we don’t want to scan. You can use the scanning distance in Real-time Scanning Parameters Settings to modify it.

Splicing Lost Retrieval Skills

Under Feature Splicing :

Move back to the previously scanned area and stay for about 2s. If still can’t continue to scan, please change to a position with obvious features. When scanning, try to scan the area with many features first, so that it is easier to splice. If it is not spliced for a long time, you can press the button on the hardware to stop scanning, then aim at the scanned area again and continue scanning.

Under Texture Splicing :

When we don’t have any features, we can artificially create features for splicing.

Under Marker Splicing:

It may be that there are few markers, so you can stick a few more on the sparse areas to continue scanning.

How to obtain higher alignment accuracy

The scanning path needs to form a closed loop using Feature Splicing.

Scan the markers with multiple angles under Marker Splicing mode to have higher scan accuracy.

When scanning medium and large objects (such as sculptures and full bodies), try to scan from the middle to the four sides, similar to the pyramid path, from top to bottom.

Multi-angle scanning will make feature splicing have stronger constraints and the accuracy is better.

Out-of-office Task List

Equipment |

Parts |

Statement |

Optional |

|---|---|---|---|

The scanner in good condition LED lights up Shaking without abnormal noise |

Scanner Calibration Plate Cables Power Adapter 6mm/3mm Markers Dongle U Disk |

Configuration File >7 days Quick Calibration Success Connected |

Power Strip HUB Spare Line Demo Samples The Product Brochure |